Grain processing is a cornerstone of the food industry, supplying the essential ingredients for a multitude of products. In this article, we introduce the 6FT-12A Corn Flour Milling Production Line Set, a cutting-edge solution designed to transform the way corn flour is produced. This production line set is a game-changer for businesses looking to enhance their grain processing operations, ensuring efficiency, quality, and versatility.

Unveiling the 6FT-12A Corn Flour Milling Production Line Set

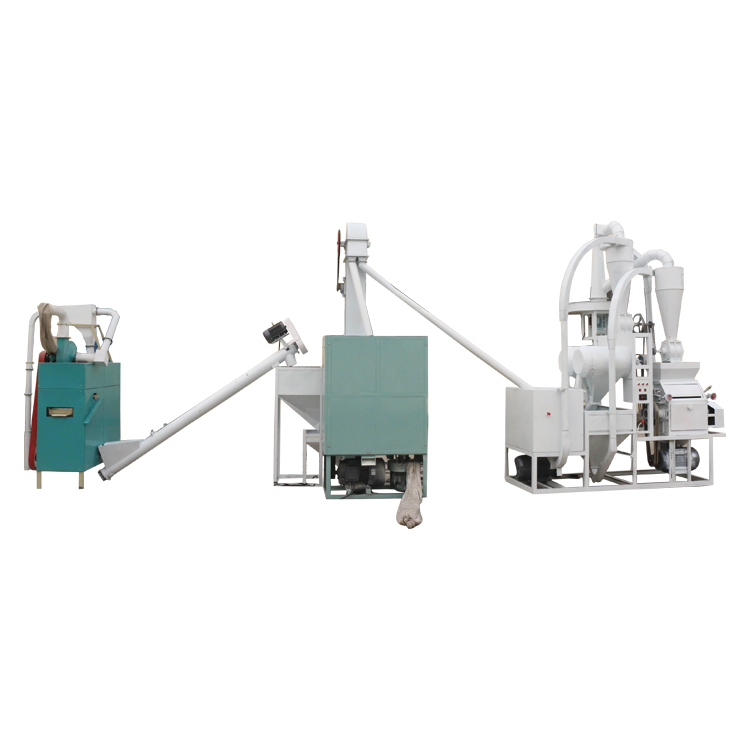

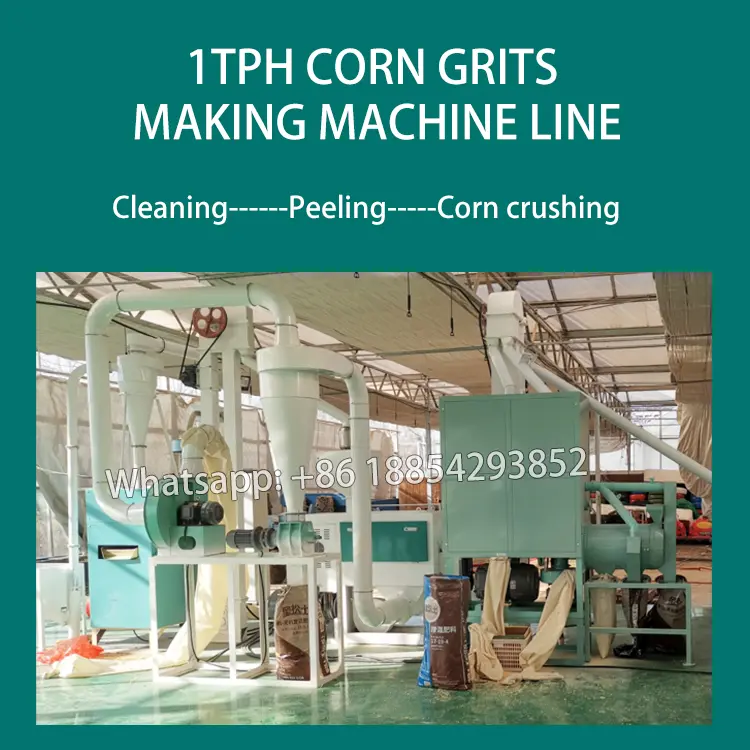

The 6FT-12A Corn Flour Milling Production Line Set is a comprehensive and integrated solution that streamlines the process of turning maize into high-quality corn flour. Comprising various components, each with its specific function, this production line offers a seamless workflow that boosts efficiency and productivity. Here's a closer look at the key elements that make up this impressive system:

Cleaning and Conditioning Unit: The journey of maize through this production line begins with a rigorous cleaning process. Impurities, foreign materials, and unwanted particles are meticulously removed to ensure that only the finest quality maize enters the milling process. This unit also conditions the maize to optimize its milling performance.

Milling Unit: At the core of the system lies the milling unit, equipped with advanced technology and precision engineering. The maize is ground into fine corn flour while preserving its nutritional value and flavor. The milling process is carefully controlled to achieve the desired particle size and consistency.

Sifting and Grading Unit: Following milling, the corn flour is subjected to a sifting and grading process. This unit separates the flour into different grades based on particle size, allowing for the creation of various products, from fine corn flour to semolina.

Packing and Bagging Unit: The final product is meticulously weighed, packaged, and bagged for distribution. The packing and bagging unit ensures that the corn flour remains fresh and protected during storage and transportation.

Key Advantages of the 6FT-12A Production Line Set

High Efficiency: The 6FT-12A Production Line Set is optimized for efficiency, streamlining the corn flour production process. By reducing processing time and labor costs, it allows businesses to meet high production demands efficiently, making it an excellent choice for grain processing operations with large-scale needs.

Consistent Quality: The precision control features integrated into the system are instrumental in ensuring that the corn flour produced consistently meets precise specifications. This level of quality control results in a uniform and dependable product with each production batch, enhancing customer satisfaction and brand reputation.

Versatility: One of the standout features of this production line is its versatility. It has the capacity to process maize into various grades of corn flour. This adaptability allows businesses to cater to diverse consumer preferences and tailor their products to the specific needs of the food industry, making it a valuable asset for businesses in the grain processing sector.

Low Maintenance: Designed with minimal maintenance requirements in mind, the 6FT-12A Production Line Set significantly reduces downtime and operational costs. This feature is not only cost-effective but also ensures that your production processes run smoothly without frequent disruptions or the need for extensive maintenance, contributing to increased productivity.

Safety Standards: Safety is a top priority in the design of this production line. It adheres to the highest safety standards to ensure a secure working environment for your staff. With safety features and mechanisms in place, the risk of accidents or injuries during operation is minimized. This not only safeguards your workforce but also ensures consumer protection, promoting trust and confidence in your products.

These advantages collectively make the 6FT-12A Production Line Set an essential and highly competitive solution for businesses in the grain processing industry. Its efficiency, quality control, versatility, low maintenance requirements, and safety features are key factors that enable grain processors to meet their production goals while maintaining product excellence and safety.

How to operate the 6FT-12A Corn Flour Milling Production Line Set?

Specific procedures and safety measures need to be followed when operating the 6FT-12A production line set. Please note that the instructions below provide a general overview, but the exact instructions may vary. Before operating, be sure to read and follow the operating manual and safety instructions in detail. Additionally, ensure that a trained operator can understand and perform the following basic operating procedures before operation:

1. Preparation:

Make sure the device is installed correctly and securely fastened.

Check the power supply and power lines to ensure proper power supply.

Check the cleanliness of equipment, including cleaning and maintaining channels and filters.

2. Start the cleaning and pretreatment unit:

Open and start the cleaning and pre-treatment unit to ensure that the grain is thoroughly cleaned and conditioned.

Follow the steps in the operating manual to ensure this phase goes smoothly.

3. Start the grinding unit:

Open the grinding unit and ensure it is properly configured to meet the required processing specifications.

Start the grain grinding process. Be sure to monitor mill output and particle size.

4. Screening and grading:

The crushed flour will be fed into a screening and grading unit where it will be classified according to the required particle size.

This step often requires adjusting screen and grading parameters to meet product specifications.

5. Packaging and packaging:

Transport flour to packing and baling unit. At this stage, the flour is packaged and bagged for subsequent distribution.

6. Monitor and adjust:

During the entire processing process, the operating status of the equipment and product quality are continuously monitored.

As needed, make necessary adjustments to ensure product meets specifications.

7. Turn off the device:

After completing the machining operation, shut down the equipment according to the procedures in the operating manual.

Perform necessary cleaning and maintenance to ensure your equipment continues to run smoothly the next time you operate it.

8. Safety precautions:

Make sure the operator has been trained on the safe operation of the equipment and emergency shutdown procedures.

Follow the safety instructions in all operating manuals, including using the safety devices and emergency stop buttons provided.

9. Regular maintenance:

Perform regular equipment maintenance, including cleaning, lubrication and parts replacement.

Follow the maintenance schedules and recommendations we provide to ensure your equipment remains in top condition.

Please note that the above is a general operation overview, and the specific operation steps and precautions may vary. Therefore, before operating the equipment, please study and follow the operating manual and safety guidelines provided by us in detail to ensure safe and effective operation.

Conculsion

The 6FT-12A Corn Flour Milling Production Line Set is a game-changer for businesses in the grain processing industry. Its integration of cleaning, milling, sifting, and packaging units, coupled with efficiency, versatility, and safety, positions it as a powerful solution for revolutionizing corn flour production. With the ability to produce high-quality corn flour efficiently and consistently, businesses can meet market demands while upholding industry standards for product quality and safety. This production line set is a cornerstone in the advancement of grain processing technology.

FAQ

What is the 6FT-12A Corn Flour Milling Production Line Set, and what is its primary function?

The 6FT-12A Corn Flour Milling Production Line Set is a comprehensive grain processing system designed to process maize into high-quality corn flour. Its primary function is to clean, mill, sift, and pack corn flour efficiently.

What is the production capacity of the 6FT-12A Production Line Set?

The production capacity can vary depending on specific models and configurations, but it is typically designed to handle a large volume of maize, making it suitable for both small and large-scale grain processing operations.

What types of maize products can be produced using the 6FT-12A Production Line Set?

This production line set is versatile and can produce various grades of corn flour, including fine corn flour and semolina. This versatility allows for a range of maize products to cater to different consumer preferences and industry needs.

What maintenance is required for the 6FT-12A Production Line Set, and how often is maintenance needed?

The system is designed for minimal maintenance requirements. Routine maintenance tasks typically include cleaning and inspection, and they can be carried out as needed to ensure smooth and efficient operation. The specific maintenance schedule may vary based on factors like usage and operating conditions.

Are there different configurations or models available for the 6FT-12A Production Line Set, and how can I choose the one that best suits my business needs?

Yes, there may be different configurations and models available to cater to varying production requirements. To choose the right one for your business, consider factors like your production capacity, budget, and specific processing needs. Consult with manufacturers or suppliers to identify the most suitable configuration.

Is the 6FT-12A Production Line Set suitable for businesses with high production demands, and how does it enhance efficiency?

Yes, this production line set is designed for businesses with high production demands. Its efficiency is achieved through streamlined processes, precise control features, and integration of cleaning, milling, sifting, and packaging units. These elements reduce processing time and labor costs, enhancing overall efficiency.

Are there financing or support options available for purchasing the 6FT-12A Production Line Set for grain processing businesses?

Some regions or countries may offer financing options or government support programs to assist with the purchase of grain processing equipment. It's advisable to inquire with local authorities or agricultural agencies for information on available support programs in your area.

What safety features are incorporated into the 6FT-12A Production Line Set to ensure a safe working environment for staff and protect consumers?

Safety is a top priority in the design of this production line. It includes safety interlocks, emergency stop mechanisms, safety guards, and heat insulation to protect both operators and consumers. Specific safety measures may vary by manufacturer and configuration.

Can the 6FT-12A Production Line Set be customized to specific processing requirements or product specifications?

Yes, we offer customization options to tailor the system to specific processing needs. Customization may include adjustments to particle size, packaging, and other elements to meet exact product specifications.

Where can I find more information about the 6FT-12A Corn Flour Milling Production Line Set, including pricing and availability?

For detailed information, pricing, and availability, please contact our customer service. They can provide specific details and assist you in making an informed decision regarding the 6FT-12A Production Line Set for your business.