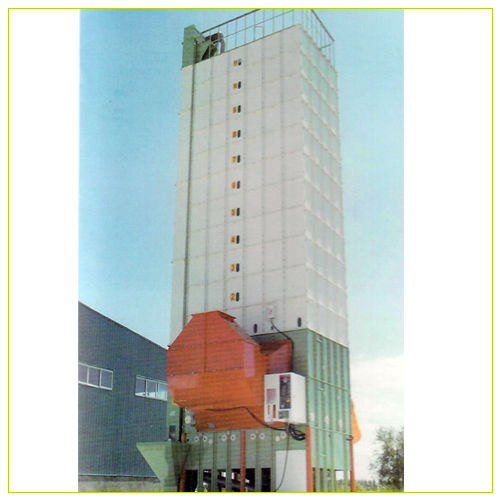

In the ever-evolving landscape of modern agriculture, ensuring the quality and safety of harvested grains is paramount. To address this critical need, Jing Cheng Machinery, a leading manufacturer from China, has revolutionized the industry with its innovative Supply Grain Drying Tower. This state-of-the-art equipment not only streamlines the post-harvest process but also significantly boosts grain preservation, making it an indispensable tool for farmers and agricultural enterprises worldwide.

Product Description

using low temperature drying technology and countercurrent preheating temperature, multi-stage drying cooling and multistage slow drying process for precipitation of the Soviet Union to ensure the uniform drying and reduce the crack growth rate

setting grain mechanism into the model, grain discharge mechanism is stable and adjustable, the grain is stable and uniform, and can automatically control box to adjust row grain size, in order to ensure the grair drying quality. To achieve food continuous drying moisture s 18%, meet the requirements of process of food processing, water> 18% food use batch drying or series of drying

equipment mechanical and electrical integration of artificial intellig lizes the online monitoring and control of the drying medium and themachine of grain

Make full use of waste heat hot air and the ability togas, reducing the heat consumption per unit.

| Technical Parameters (model) | nhtd20 | NHTD30 | NHTD50 |

| Daily processing C(T/D) | 200 | 300 | 500 |

Introduction to Jing Cheng Machinery

Jing Cheng Machinery, nestled in the heart of China's vibrant manufacturing hub, has been at the forefront of agricultural machinery innovation for decades. Renowned for its commitment to quality, efficiency, and environmental sustainability, the company has carved out a niche for itself by designing and producing cutting-edge equipment that meets the diverse needs of the global agricultural sector. Its Supply Grain Drying Tower is a testament to this dedication and innovation.

The Advantages of Jing Cheng's Grain Drying Tower

Efficient Drying Technology: The Grain Drying Tower from Jing Cheng Machinery employs advanced drying technology that ensures rapid and even drying of grains, minimizing moisture content to optimal levels. This not only prevents mold growth and spoilage but also enhances the overall quality and marketability of the grain.

Energy Efficiency: Recognizing the importance of sustainability, Jing Cheng's drying towers are designed for maximum energy efficiency. Utilizing advanced heat recovery systems and optimized airflow patterns, they minimize energy consumption while maximizing drying performance.

Versatility: Suitable for a wide range of grains including wheat, corn, rice, and more, this drying tower offers unparalleled versatility. Its modular design allows for easy adaptation to different capacities and crop types, making it an ideal investment for farmers of all sizes.

Durability and Maintenance: Built with high-quality materials and precision engineering, Jing Cheng's Grain Drying Tower is designed for long-term durability. Additionally, its user-friendly maintenance features ensure minimal downtime and maximum uptime, contributing to overall cost-effectiveness.

Intelligent Control System: Equipped with an intelligent control system, the drying tower allows for precise monitoring and adjustment of temperature, humidity, and other critical parameters. This not only ensures optimal drying conditions but also simplifies operation and reduces the need for manual intervention.

Why Choose Jing Cheng Machinery?

Quality Assurance: With stringent quality control measures in place, every Grain Drying Tower from Jing Cheng Machinery undergoes rigorous testing to ensure compliance with international standards.

Customer Support: Jing Cheng Machinery offers comprehensive customer support, including installation guidance, operator training, and after-sales service, ensuring a seamless experience for customers.

Cost-Effectiveness: Despite its advanced features, Jing Cheng's Grain Drying Tower offers exceptional value for money, making it an affordable solution for farmers looking to enhance their harvest handling capabilities.

Conclusion

In conclusion, Jing Cheng Machinery's Supply Grain Drying Tower is a game-changer in the agricultural industry. Its combination of efficient drying technology, energy efficiency, versatility, durability, and intelligent control system sets it apart as a premier choice for farmers and agricultural enterprises worldwide. By investing in this innovative equipment, you are not only improving the quality and safety of your harvested grains but also enhancing your overall operational efficiency and profitability. Choose Jing Cheng Machinery's Grain Drying Tower today and embark on a journey towards agricultural excellence.

FAQ

1. What is the primary function of a grain drying tower?

The primary function of a grain drying tower is to efficiently and uniformly reduce the excess moisture content in harvested grains (such as rice, wheat, corn, etc.) to safe storage levels, thereby extending their shelf life, minimizing the risk of mold growth, and preserving their nutritional value and color.

2. What are the main features of a grain drying tower?

The main features of a grain drying tower include:

High Efficiency and Energy Saving: Low power consumption and operating costs.

Versatility: Adapts to the drying patterns of different types of grains, ensuring even heat distribution.

Intelligent Control: Equipped with hot air control and grain level control systems for precise drying process management.

Modular Design: Easy to transport and install, suitable for various scales and types of grain processing facilities.

Eco-Friendly and Economical: Can utilize byproducts like rice husks as fuel, with recyclable combustion products.

3. When is a grain drying tower particularly important?

A grain drying tower is particularly important in the following situations:

Humid or Rainy Regions: To promptly dry grains and minimize mold-related losses.

Large-Scale Grain Production: To enhance drying efficiency and reduce labor costs.

Ensuring Grain Safety: By controlling moisture levels, extending storage duration, and safeguarding grain quality.

4. Who are some of the manufacturers of grain drying towers in China?

China boasts several professional manufacturers of grain drying towers, such as Jing Cheng Machinery Equipment Co., Ltd. These manufacturers leverage advanced production technologies and rigorous quality control to provide efficient and reliable grain drying equipment.

5. How do I choose the right grain drying tower?

Factors to consider when selecting a grain drying tower include:

Grain Type and Production Volume: Determine the tower's capacity and specifications based on the grain type and processing volume.

Drying Effectiveness: Evaluate the tower's drying efficiency, uniformity, and impact on grain quality.

Operating Costs: Consider energy consumption, maintenance expenses, and equipment depreciation.

After-Sales Service: Choose a manufacturer with a comprehensive after-sales service system to ensure timely technical support and maintenance.

6. What precautions should be taken during the operation of a grain drying tower?

During operation, the following precautions should be observed:

Regular Inspections and Maintenance: Ensure all components are in good condition to prevent breakdowns.

Temperature Control: Maintain optimal hot air furnace temperatures to avoid compromising grain quality.

Adequate Ventilation: Ensure proper air circulation within the drying chamber to prevent moisture accumulation.

Adherence to Operating Procedures: Follow operating instructions strictly to prevent equipment damage or suboptimal drying results.

In summary, grain drying towers supplied by Chinese factories offer high efficiency, energy savings, and intelligent control, catering to various grain processing needs. When selecting and operating these towers, comprehensive consideration of various factors is crucial to maximize drying effectiveness and economic benefits.