1.Top grade wheat/barley/pearl millet flour milling machine Intruduction

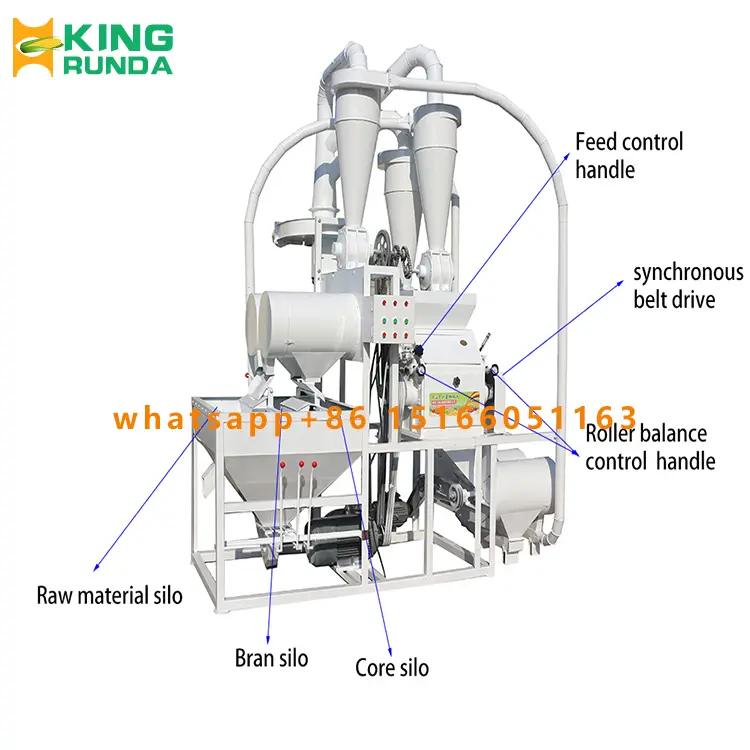

Two round sifters first extract wheat core to grind wheat core purely into white wheat flour in highest quality. After extracting wheat core, wheat skin is separated and stored in middle silo for further grinding and flour extracted. Wheat core and wheat skin are milled separated. Skin/bran does not mix with wheat flour, that is why it produces high quality wheat flour.Whole procedure is automatic, wind transmit material. Feed grain into silo, automatically take grain to grind then auto sifting and receive output. Only needs one person to operate.

What is new?

Three silos designed to hold raw material, big bran, wheat core.

Two round sifter first extracts wheat core.

Another two round sifter extracts wheat flour.

2.Top grade wheat/barley/pearl millet flour milling machine structure

How it works?

1st time extract wheat core

2nd time grind wheat core

3rd time grind wheat skin

It can also be made of SST according to customer's request.

3.Top grade wheat/barley/pearl millet flour milling machine final products

4.Top grade wheat/barley/pearl millet flour milling machine advantage

1. Improved technology from traditional flour mill, simpler structure, easy to operate.

2. Adopt chain drive transmission system, more energy saving, low noise, and low maintenance cost.

3. Famous brand rollers which last long year with no need replacement.

4. Besides wheat, it can be used to produce flour from maize, beans or other cereal grains.

5. Machine frame uses standard steel plate with powder coated finish, nice looking and work stably to reduce shaking.

6. Besides wheat flour, after peeling or crushing, beans can also be used to be ground on the flour mill to produce cereal grain flour, for example, wheat, black eye bean, lentil, yellow pea, gram, etc.

5. Our showroom

979.webp)