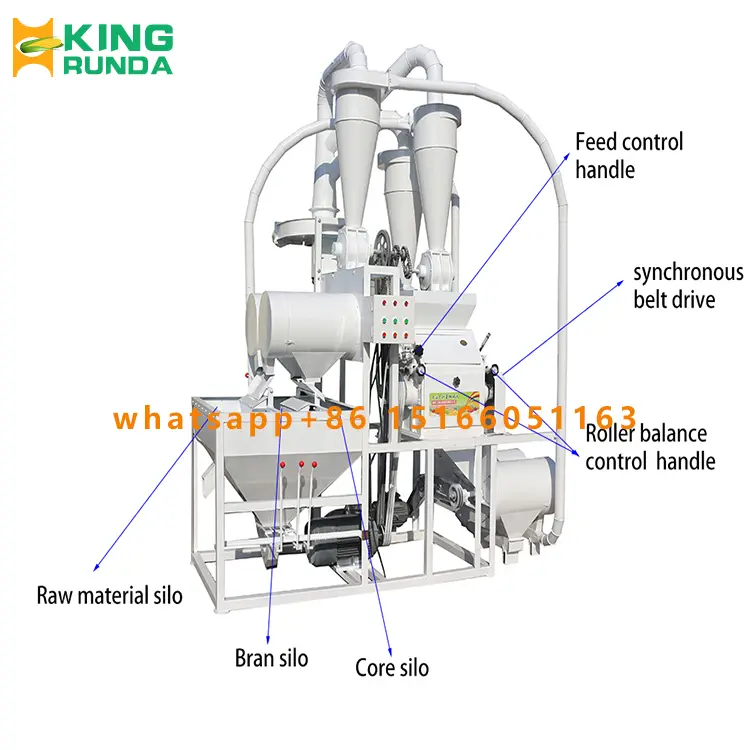

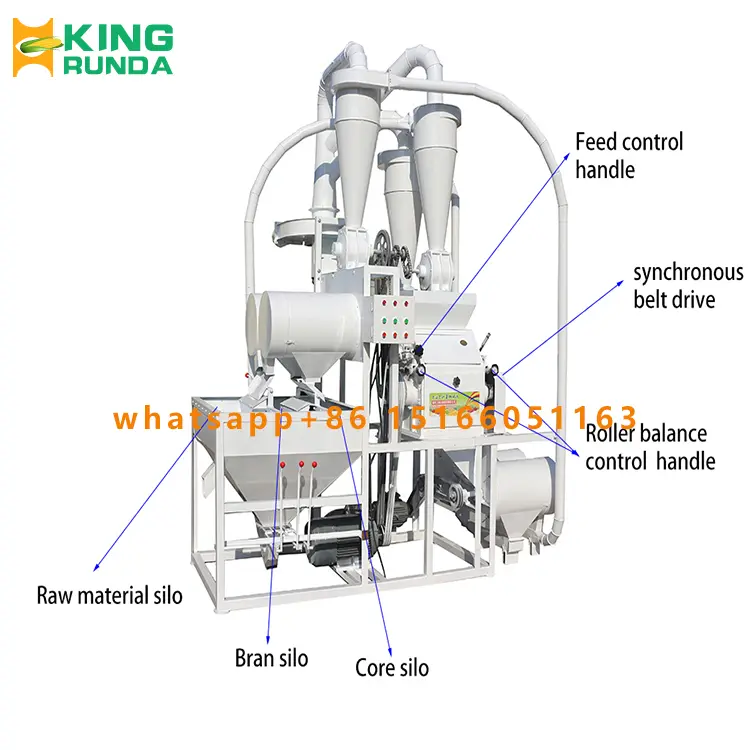

High Grade Wheat Semolina Flour Milling Machine Introduction

It is our new high technology designed to produce high quality white wheat flour. Structure is upgraded to have three silos and four round sifters. Two round sifters first extract wheat core to grind wheat core purely into white wheat flour in highest quality. After extracting wheat core, wheat skin is separated and stored in middle silo for further grinding and flour extracted. Wheat core and wheat skin are milled separated. Skin/bran does not mix with wheat flour, that is why it produces high quality wheat flour.Whole procedure is automatic, wind transmit material. Feed grain into silo, automatically take grain to grind then auto sifting and receive output. Only needs one person to operate.

It is our new high technology designed to produce high quality white wheat flour. Structure is upgraded to have three silos and four round sifters. Two round sifters first extract wheat core to grind wheat core purely into white wheat flour in highest quality. After extracting wheat core, wheat skin is separated and stored in middle silo for further grinding and flour extracted. Wheat core and wheat skin are milled separated. Skin/bran does not mix with wheat flour, that is why it produces high quality wheat flour.Whole procedure is automatic, wind transmit material. Feed grain into silo, automatically take grain to grind then auto sifting and receive output. Only needs one person to operate.

It is for high grade market. It places on ground, feed material from ground, no need elevator. Receive flour, bran from ground, easy to operate. It can produce wheat and cereal grain flour, wheat semolina flour, standard life. Flour fineness can be adjusted from 90 mesh to 120mesh

Three silos designed to hold raw material, big bran, wheat core.

Two round sifter first extracts wheat core.

Another two round sifter extracts wheat flour.

According to customer's different, Wheat Semolina Flour Milling Machine can be made of SST material.

2.High Grade Wheat Semolina Flour Milling Machine Working effect

3. How is High Grade Wheat Semolina Flour Milling Machine Works?

1st time extract wheat core

2nd time grind wheat core

3rd time grind wheat skin

4. High Grade Wheat Semolina Flour Milling Machine Advantage

1. Efficiency: This machine can process large quantities of wheat quickly and efficiently, reducing manual labor and time required for milling.

2. Consistency: Modern milling machines ensure consistent quality of flour, meeting specific standards and requirements for various uses, such as baking or pasta making.

3. Flexibility: They can produce different types of flour (e.g., all-purpose, whole wheat, pastry flour) by adjusting milling parameters like speed, grain size, and sieving.

4. Precision: Advanced milling machines can finely control the milling process, resulting in precise flour particle sizes, which is crucial for achieving desired baking properties.

5. Waste Reduction: These machines are designed to minimize waste by efficiently extracting flour from wheat grains while separating out impurities like bran and germ.

6. Cost-effectiveness: While initial investment may be high, over time, the efficiency and consistency of milling machines can lead to cost savings compared to manual or less efficient milling methods.

7. Hygiene and Safety: Modern milling machines are built with hygiene and safety standards in mind, reducing the risk of contamination and ensuring a safe working environment for operators.

5. Our showroom

Qingdao Jing Cheng Machinery (Shandong Kingrunda Machinery Co., Ltd) is a professional manufacturer with more than 20 years experience for all kinds of grain processing machines.Grain/Bean Dehuling & Peeling Machine for,lentil/pea/mung/faba bean/black eye bean/ chick pea,soyabean/tiger nut/oat/quinoa/millet/sorghum,etc

Maize Grits Milling Machine

Wheat Flour Milling Machine

Grain cleaning machine...etc

I hope we will support you and be your business partner.Thank you!

Whatsapp: +86 15166051163

Website: www.beanpeelingmachine.com

Email: sales2@kingrunda.com

Wechat : kathy18553250968

851.webp)