Introduction for corn grits making machine

The 6FT-PD1C Chinese Corn Peeling and Grits King is a new generation of corn processing machinery developed by our company. It has the advantages of beautiful appearance, compact structure, simple operation, energy saving and high efficiency, sturdy and durable. This machine overcomes the common shortcomings of all domestic corn processing machinery, sets off a revolution in corn processing machinery, and solves the technical difficulties of corn processing machinery such as boring operation and slow removal of impurities in history. The machine is also equipped with a current display system, so that the internal pressure in the machine working room and the peeling effect of the material can be clearly seen at a glance. It also has a newly added automatic adjustment system for discharging, which can keep the machine in the best working condition. It is currently the most advanced in the country. The corn peeling processing machine is actually the best equipment for corn finishing. One machine can be used for multiple purposes. It can also process rice, wheat, sorghum and other miscellaneous grains, saving labor and time. The finished corn kernels produced are smooth in color, clean without navel, and have high yield. High, it is currently the most advanced corn and grains deep processing machinery.

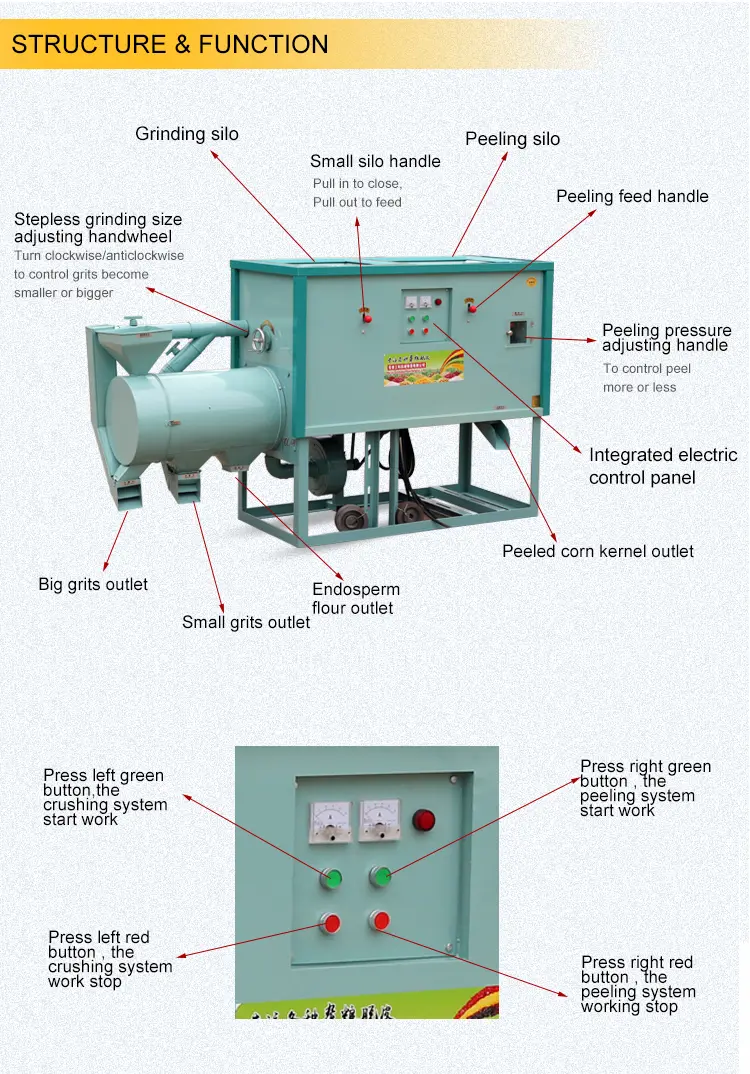

Structure and function for corn grits making machine

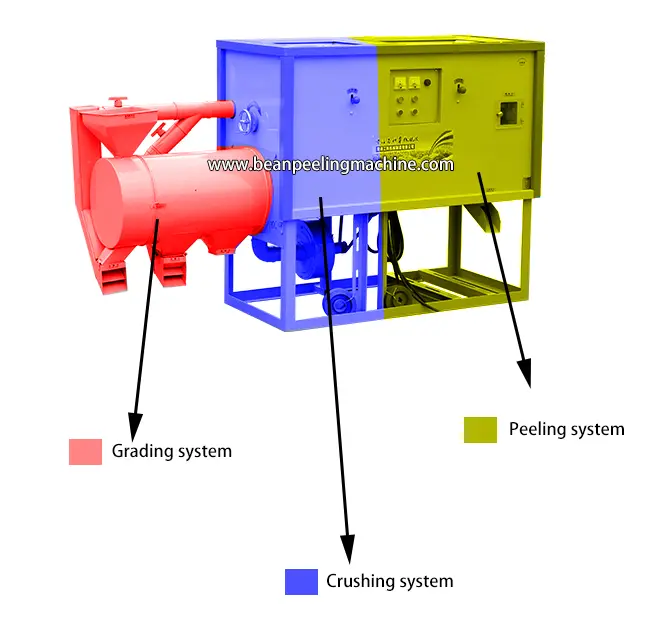

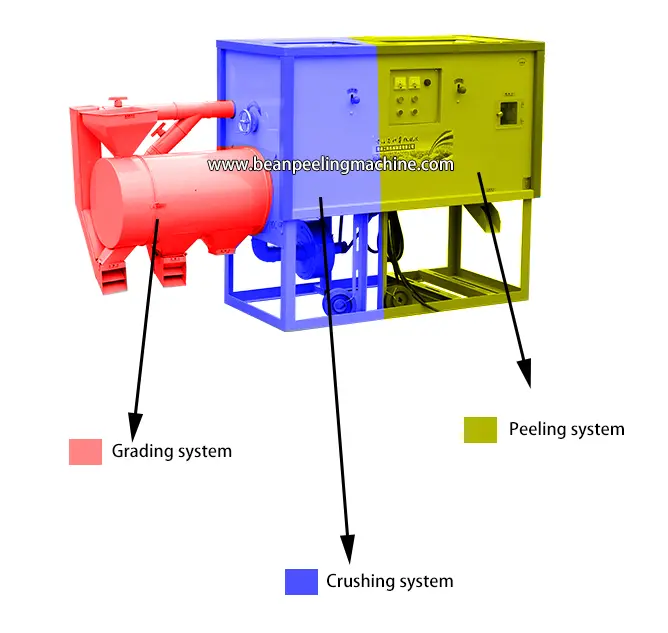

After corn, rice, wheat and other materials enter the peeling chamber from the hopper, they move toward the exit under the rotation of the propelling ribs. In the peeling chamber, due to the gradual reduction of the working room volume and the influence of the resistance of the machine parts, the density between the rice grains decreases, and the pressure increases with the to increase, the squeezing and friction in the machine are strengthened, the rollers continue to turn and push, and the rice grains are gradually cleaned due to the friction and peeling between the machine parts. The dehulled rice grains, kernels and bran peels are automatically separated through the separation device, and the finished dehulled kernels flow out through the discharge port. The chaff is discharged from the waste outlet at the back.

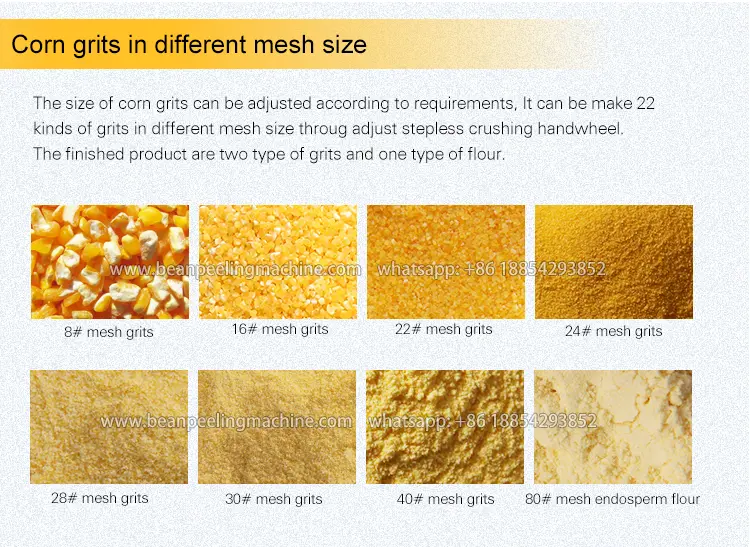

The cleaned corn kernels are poured into the hopper of the grit making machine, and the air adjustment handle is pulled out. It travels forward through the traction clutch crushing device and is crushed in the process. The crushed products enter the grading system and pass through the three-separating circular screen. Separate and separate the corresponding finished products from the three finished product outlets. In this process, the micro-husks in the corn grits are sucked away by the action of the wind through the action of the fan and the wind net, thereby achieving the purpose of cleaning the grits. The wind force can be adjusted by the wind control handle. The micro-skin blown out by the fan is naturally packed in a homemade thin cloth bag with a length of 2 meters.

Peeling: :remove outer skin, take out root and black hilum, to get best nutrient part out of corn seed for further processing.

Grinding: grind peeled kernel into grits.

Grading: Grad grits into different mesh size.

Techniacl paremeter for corn grits making machine

6FT-PD1C Corn grits machine

Including peeling, grinding and grading.

Power: 11kw 4kw

Capacity:500- 600kg/h (input)

Packing size:2300x800x1440mm

CBM: 2.6.

About our company

We are professional manufacturer for

Grain/Bean Dehuling & Peeling Machine for

lentil/pea/mung/faba bean/black eye bean/ chick pea

soyabean/tiger nut/oat/quinoa/millet/sorghum,etc

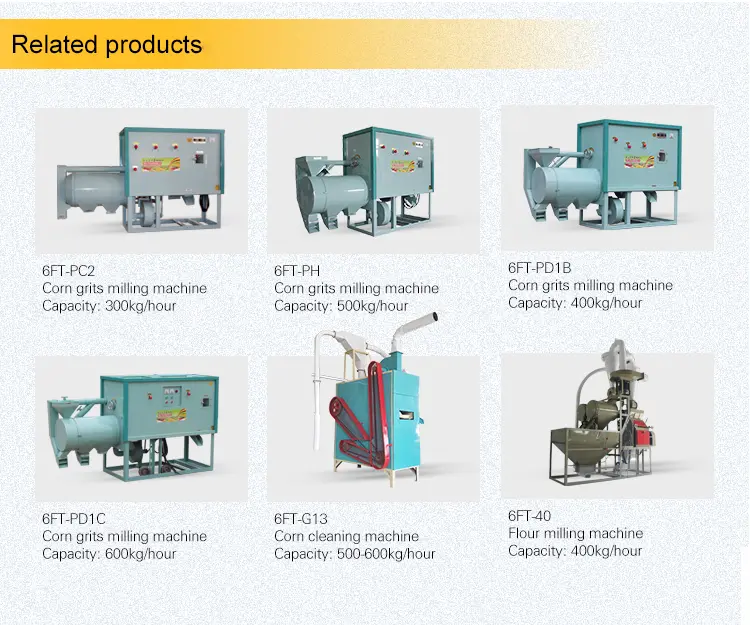

Maize Grits Milling Machine

Wheat Flour Milling Machine

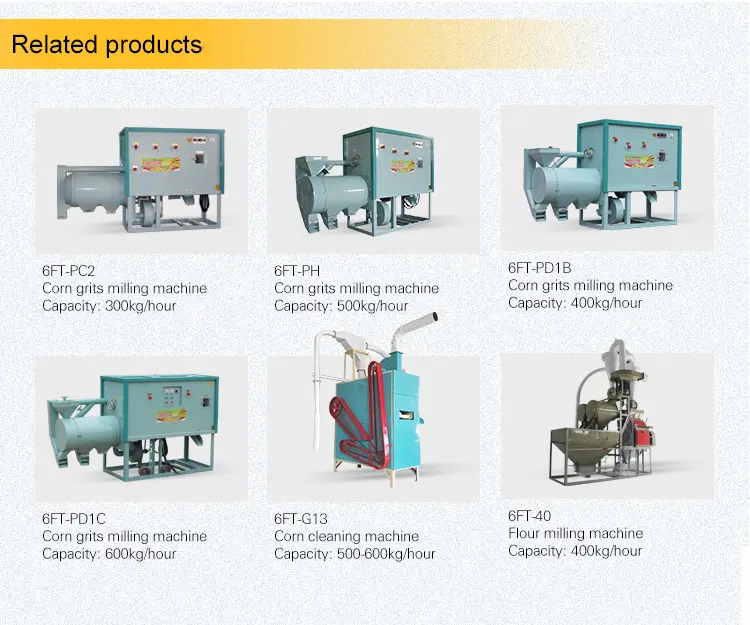

874.webp)