973538.webp)

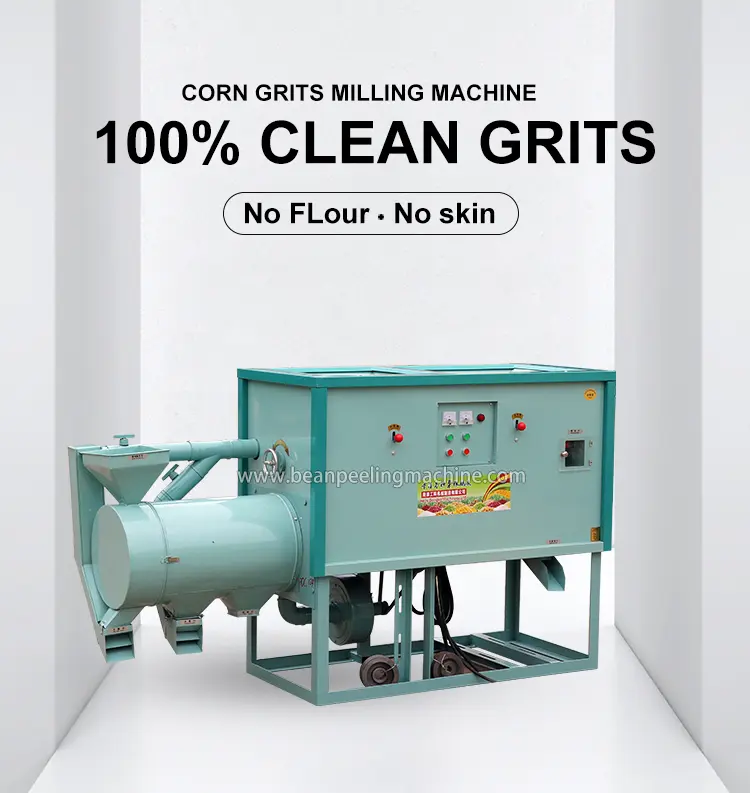

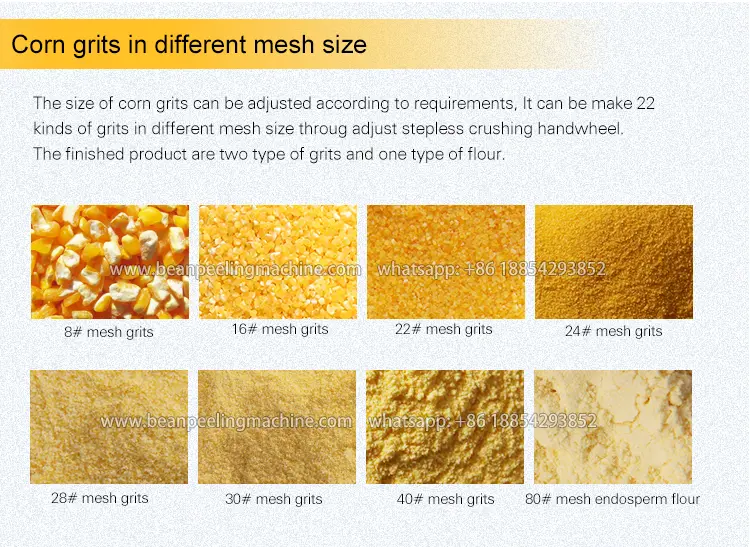

Introduction for corn grits making machine

The corn grits making machine is a professional device used for processing corn into corn grits. The following is an introduction to it from aspects such as its structure, working process, performance characteristics, etc.:

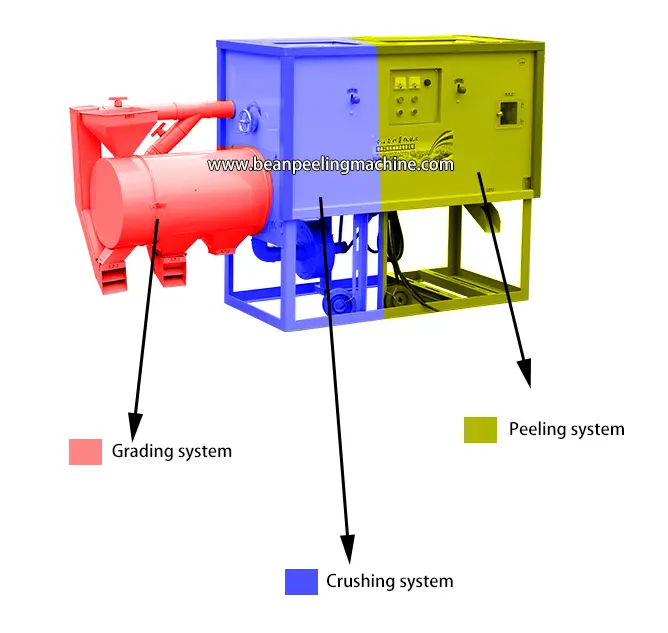

Peeling and Germ Removal Device: Generally, it includes peeling rollers and a germ remover. The peeling rollers remove the outer skin of the corn through the action of friction and extrusion. The germ remover takes advantage of the differences in shape, density, etc. between the corn germ and other parts of the corn kernel to separate the corn germ, which improves the taste and quality of the corn grits and is also beneficial for extending the storage time.

Crushing Device: It is the core component of the corn grits making machine, mainly consisting of crushing rollers, hammer plates, etc. The surface of the crushing rollers has special patterns or tooth shapes. Through the squeezing and shearing action between two relatively rotating crushing rollers, the corn kernels are crushed into corn grits of different sizes. The hammer plate type crushing device, on the other hand, uses the hammer plates rotating at high speed to strike the corn, making it break.

Screening Device: It is mostly composed of sieve meshes with different mesh counts and is installed inside the machine or near the discharge port. The crushed corn grits are screened through the sieve meshes. The corn grits that meet the requirements pass through the sieve meshes and become finished products or enter the next process, while those that do not meet the particle size requirements are returned to the crushing device for further processing.

Advantage of corn grits making machine

High Efficiency: It has a high production efficiency. Large-scale corn grits making machines can process several tons of corn per hour, which can meet the needs of large-scale production.

High Precision: It can precisely control the particle size of corn grits. The processed corn grits have a uniform particle size, regular shape, and stable quality.

Stability: Made of high-quality materials and adopting advanced manufacturing processes, the key components are specially treated. The equipment has a sturdy structure, stable operation, can work continuously for a long time, and has a low failure rate.

Ease of Operation: It is simple and convenient to operate. Equipped with an intuitive operation panel and control system, operators can master the operation method of the equipment proficiently after simple training, and can easily set and adjust various parameters.

Multifunctionality: Some corn grits making machines, by replacing some components or adjusting parameters, can also be used to process other grains such as wheat and sorghum. They have a certain degree of versatility, which improves the utilization value of the equipment.

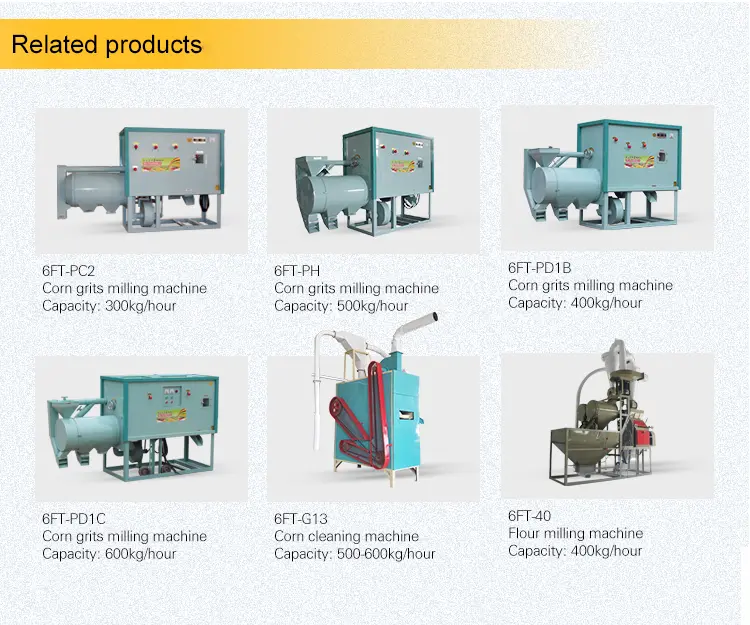

Corn grits display

782745.webp)

Uniform Particle Size

Through the coordination of the crushing device and the screening device, the corn grits making machine can precisely control the particle size of the corn grits. For example, the crushing rollers with special patterns or tooth shapes on the surface are used to extrude and shear the corn, and then through the screening of sieve meshes with different mesh counts, the processed corn grits can have a consistent particle size, without overly large or small particles, meeting the taste and cooking requirements of different consumers for corn grits.

Regular Shape

In the processing process, advanced corn grits making machines can ensure that the shape of the corn grits is relatively regular. Unlike manual processing, which may result in corn grits with various and uneven shapes, the corn grits produced by the machine mostly present a relatively uniform flake or granular shape, with a more neat and beautiful appearance, enhancing the visual effect and market attractiveness of the product.

Good Taste

Impurity Removal: The corn grits making machine usually comes with a peeling and germ removal device, which can effectively remove the outer skin and germ of the corn. The outer skin of the corn has a rough taste, and the corn germ contains a relatively high amount of fat, which is prone to deterioration and produce an unpleasant smell during storage. After removing them, the taste of the corn grits can be made more delicate and pure.

Complete Retention of Nutrients: With reasonable processing technology and parameter settings, the original nutrients of the corn can be retained to the greatest extent during the production of corn grits, making the porridge cooked with corn grits or other foods made from it have a rich and mellow taste, full of the unique sweet flavor of corn.

We specialize in the customization service of corn grits making machine equipment, which can fully meet the personalized needs of our customers. In terms of production capacity, we have a professional technical team and rich industry experience. We can create a tailored production capacity plan for our customers based on various factors such as their actual expected production scale, operation plan, and market demand.

Whether it is a small processing workshop expecting a production output of several hundred kilograms per hour or a large food enterprise aiming for a production capacity of several tons or even higher per hour, we can ensure that the customized corn grits making machine equipment operates stably and efficiently by optimizing the core components of the equipment. This includes using a more efficient power system, adjusting the operating parameters and configurations of the crushing and screening devices, as well as rationally planning the overall layout and technological process of the equipment. In this way, we can precisely achieve the production capacity requirements customized by our customers and help them achieve efficient and sustainable development in the field of corn grits production.

4TPH Corn grits making machine line

510.webp)

762.webp)