In recent years, quinoa has gained global recognition as a superfood due to its rich nutrient profile, high protein content, and gluten-free nature. However, despite its popularity, the process of removing quinoa's tough outer shell to make it suitable for consumption can be a labor-intensive and time-consuming task. This is where the quinoa peeling/shelling machine comes into play. This state-of-the-art piece of machinery is designed to automate the laborious process of quinoa dehulling, ensuring high-quality results, increased efficiency, and scalability for businesses involved in quinoa processing.

The Importance of Quinoa Peeling/Shelling

Quinoa (Chenopodium quinoa) is a pseudocereal native to the Andean region of South America. While the plant’s seeds are highly nutritious, they are surrounded by a bitter-tasting outer hull or shell. This outer shell, known as saponin, acts as a natural deterrent to insects and animals. While saponins have anti-nutritional properties and make the seeds unpalatable for direct consumption, they are removed during the quinoa processing phase to make the seed edible.

Before quinoa is ready for consumption or export, it must undergo a delicate process of peeling or shelling. The outer hull is removed in a way that ensures the seed remains intact and retains its nutritional value. This is a critical step in quinoa processing, especially for businesses involved in large-scale quinoa production.

Our quinoa peeling/shelling machine represents a technological breakthrough in quinoa processing. Designed to address the challenges of traditional methods, this advanced machinery automates the peeling process, reducing labor costs, improving efficiency, and enhancing the overall quality of the final quinoa product.

Introduction for our quinoa peeling machine

Our quinoa peeling machine is a specialized agricultural equipment designed to remove the bitter saponin layer from quinoa seeds, making them safe for consumption and enhancing their palatability. Here's a detailed introduction to its features, working principles, and applications:

1. Core Functionality

The primary purpose of a quinoa peeling machine is to eliminate the natural saponin coating on quinoa grains. Saponins, which act as a natural pesticide in quinoa plants, impart a bitter taste and can cause digestive irritation if consumed in large quantities. The machine ensures thorough removal of this layer while preserving the nutritional integrity of the seeds.

2. Working Principles

Quinoa peeling machines employ dry processing technologies to avoid water usage and nutrient loss. Key mechanisms include:

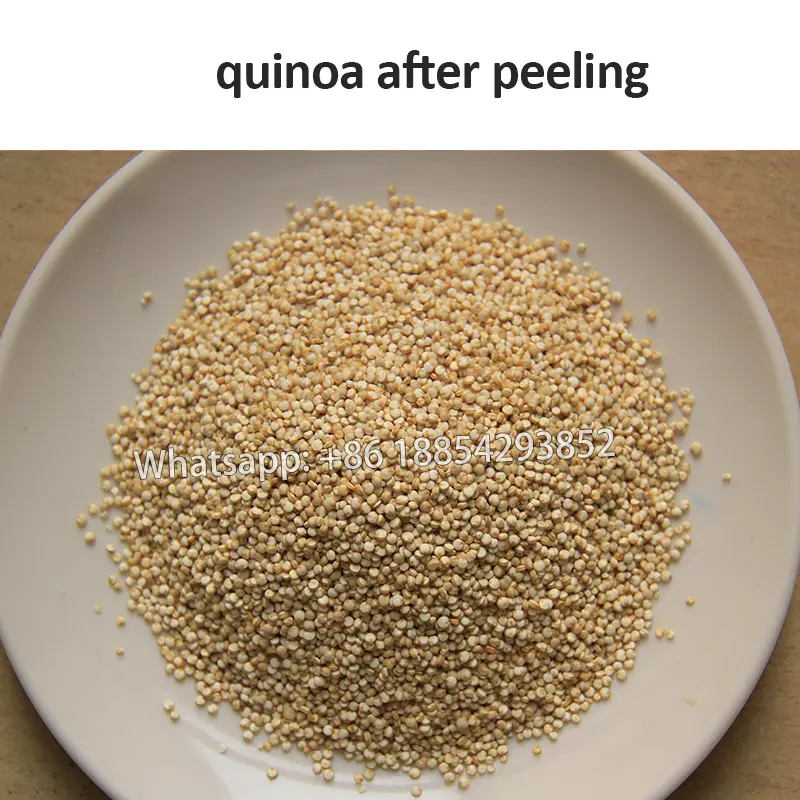

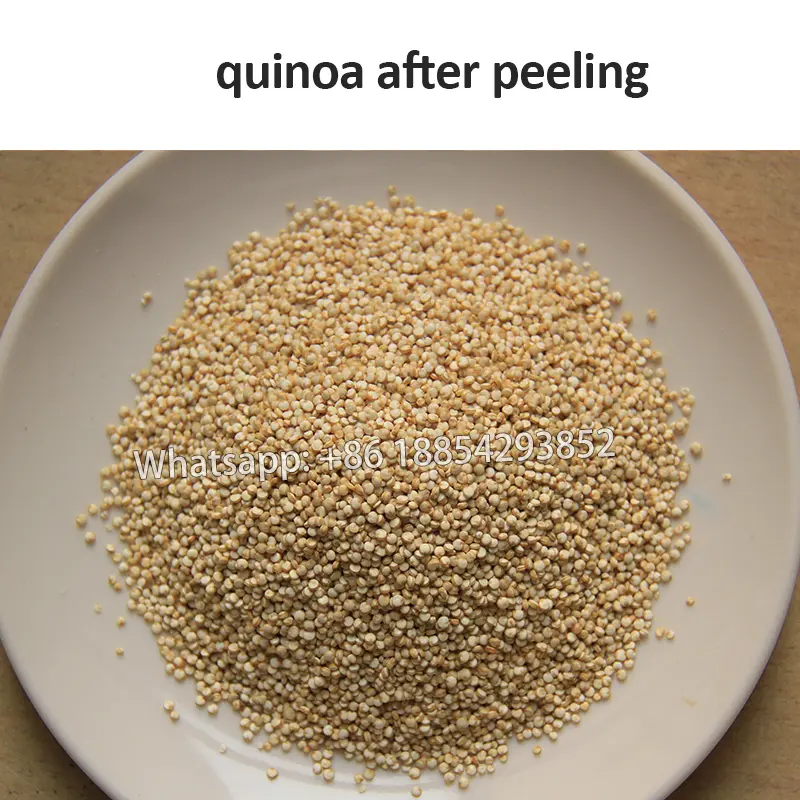

Finished product by our quinoa peeling machine

More Effects of (Saponin-Removed Quinoa) through Mechanical Processing

These advancements significantly enhance its commercial value and culinary appeal:

1. Sensory Quality Enhancement

2. Nutrient Retention & Bioavailability Improvement

Detail image for our quinoa peeling machine

Key Features of the Quinoa Peeling/Shelling Machine

High Efficiency and Speed

The quinoa peeling/shelling machine is engineered to handle large volumes of quinoa quickly and efficiently. With its high processing speed, the machine can peel and shell quinoa at a rate far exceeding manual methods. This makes it ideal for commercial quinoa processing operations, where time is of the essence and high output is necessary to meet demand.

Gentle Processing

One of the biggest advantages of the quinoa peeling/shelling machine is its ability to gently process quinoa. Unlike traditional methods, which often result in damaged or broken quinoa seeds, the machine ensures that the quinoa remains intact and unbroken. This not only improves the quality of the product but also reduces waste, making the production process more efficient.

Adjustable Settings

The quinoa peeling/shelling machine features adjustable settings that allow operators to fine-tune the peeling process. The machine can be calibrated to process different varieties of quinoa, ensuring versatility and adaptability in various production environments. Operators can adjust the peeling intensity and speed to match the specific requirements of the quinoa being processed, further enhancing the machine's efficiency.

Automation and Labor Reduction

By automating the peeling and shelling process, the quinoa peeling machine significantly reduces the need for manual labor. This helps to lower labor costs, increase overall productivity, and reduce human error. Operators can focus on other tasks while the machine does the heavy lifting, making it a valuable addition to any quinoa processing facility.

Minimal Quinoa Loss

The quinoa peeling/shelling machine is designed to minimize product loss. By using precision engineering, the machine efficiently removes the outer hull without wasting quinoa seeds. This leads to a higher yield, which is critical for businesses seeking to maximize their profits and reduce waste.

Durability and Long-Lasting Performance

Built with high-quality materials, the quinoa peeling/shelling machine is designed for durability and long-lasting performance. The components are made of sturdy, corrosion-resistant materials, ensuring that the machine can withstand the rigors of continuous use. With proper maintenance, the machine can operate effectively for many years, providing excellent return on investment.

Easy Maintenance

Maintenance is simple and straightforward. The machine is designed with easy access points for cleaning and servicing, which reduces downtime and ensures that the machine remains in optimal condition. Regular maintenance ensures that the machine continues to operate at peak efficiency, reducing the risk of costly repairs or replacements.

The quinoa peeling/shelling machine represents a significant advancement in quinoa processing technology. By automating the labor-intensive task of peeling and shelling quinoa, the machine helps businesses improve efficiency, reduce labor costs, and produce high-quality quinoa that meets the growing global demand for this superfood. With its ability to handle large volumes, minimize waste, and maintain the integrity of the quinoa seed, the quinoa peeling machine is an invaluable tool for any quinoa processing operation.

As the demand for quinoa continues to rise, investing in a quinoa peeling/shelling machine is not only a smart business decision but also a step toward ensuring the long-term success of any quinoa-based business. The benefits of automation, increased production capacity, and consistent quality make this machine a crucial asset in the modern quinoa industry.

About our company

Qing Dao Jing Cheng Machinery Co.,Ltd (previously it was Shandong Kingrunda Machinery Co.,Ltd). We wish to be your exclusive Quinoa peeling equipment supplier and reliable business partner.

"Have quality win reputation. Have reputation build brand. Have brand get market"is our management concept. We get together talented engineers of this industry in Kingrunda and deliver first rate product and technical service to customers home and abroad.

Kingrunda business originates from flour mill, SB series combined dehuller rice mill, 6NF series air-jet rice mill, disk mill and single screw self-cooked food extruders, etc. Driven by foreign trade growth in recent years, we diversify our business and develop very fast. We have established strong and long term cooperation relationship with customers in more than 20 countries or areas including US, UK, Spain, Sweden, India, Sri Lanka, Bangladesh, Vietnam, Indonesia, Nigeria, etc. To better serve customers and subdivide market, we expand our team, launch new projects and a few business departments gradually have come into being which make communication with customers much easier. Kingrunda strives to be a new type star company which can satisfy both employees and customers.

Contact Us

We are committed to providing our customers with top-quality quinoa peeling/shelling machines that help streamline your production process and deliver exceptional results. If you have any questions, need more information, or would like to inquire about pricing, please don't hesitate to contact us. We're here to assist you every step of the way.