Introduction of Corn grits making machine

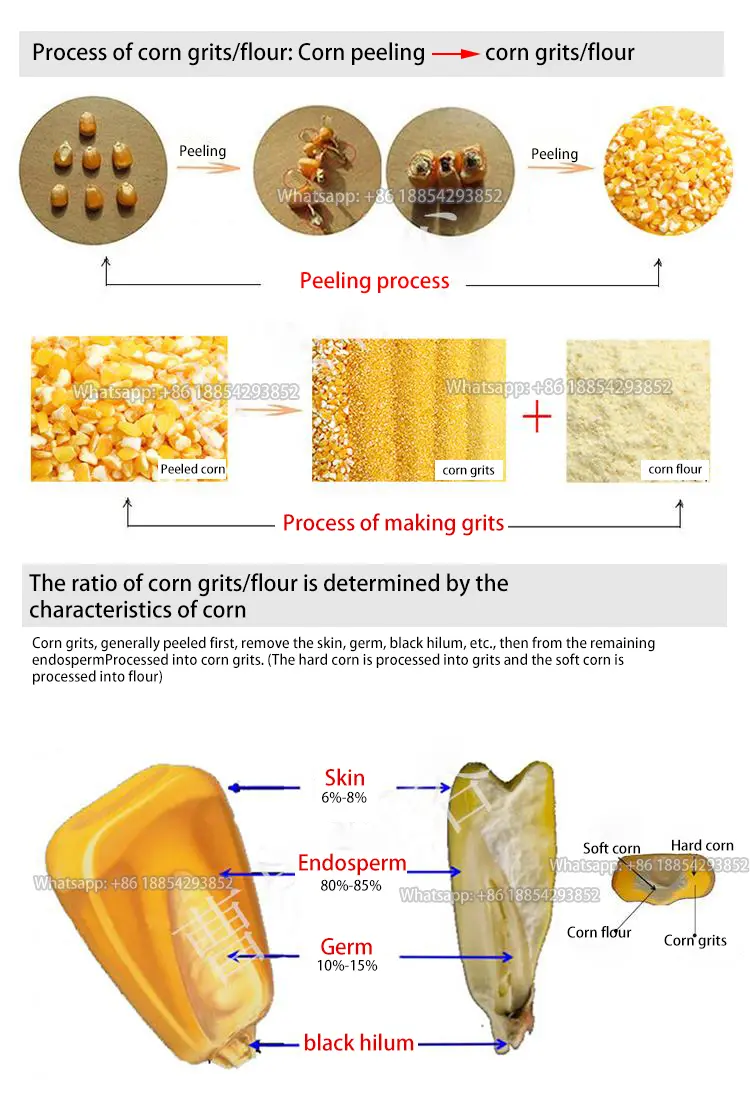

corn grits making machine is mainly composed of a peeling system, a grits production system, a finished - product grading system, a dust removal system, a frame, and a power distribution system. It can carry out processes such as cleaning, peeling, germ removal, root removal, black navel removal, crushing, grinding, grading, and polishing of corn, and produce corn grits of different granularities and corn flour of different mesh numbers at one time.

The machine is easy to operate. Some models are also equipped with an indicator display function, which can ensure the stable and normal operation of the machine.

Advantage of corn grits making machine

High processing efficiency: It can operate continuously, processing hundreds of kilograms of corn per hour, which greatly improves the efficiency of corn processing and meets the needs of large-scale production.

Good product quality: It can complete a series of processes such as peeling, germ removal, crushing, grinding, and grading. The produced corn grits have uniform particles and a pure color, and the corn flour is fine. Moreover, it maximally retains the nutritional components of corn.

Multifunctionality: It can not only process corn into corn grits of different granularities but also simultaneously produce corn flour of different mesh numbers, achieving the use of one machine for multiple purposes, increasing the use value of the equipment and economic benefits.

Simple operation: The operation interface of the equipment is simple and easy to understand, and the control system has a relatively high degree of automation. Operators can master the operation method proficiently after simple training, reducing labor costs and operation difficulty.

Low maintenance cost: It adopts advanced design and high-quality materials, with a sturdy and durable structure. The key components have a long service life, reducing the maintenance frequency of the equipment and the cost of replacing components. At the same time, the maintenance work of the equipment is relatively simple, making it convenient for operators to carry out daily maintenance.

Environmentally friendly and energy-saving: It is equipped with an efficient dust removal system, which can effectively collect the dust generated during the processing, reduce dust emissions, improve the working environment, and meet environmental protection requirements. In addition, emphasis is placed on energy conservation in the design of the power configuration and transmission system, reducing energy consumption and saving production costs.

Strong adaptability: It can adapt to the processing of corn of different varieties and moisture contents. By adjusting the relevant parameters of the equipment, it can ensure the production of high-quality products under various raw material conditions.

800662.webp)

In the supply of corn grits making machines, we always adhere to the customer-centric concept. Just like a precise navigation system that always locks onto its destination, regardless of whether the customer's needs are large or small, simple or complex, we can, like skilled tailors who take accurate measurements for each customer, meticulously create exclusive corn grits making machine solutions tailored to their individual requirements.

Our customers are located all over the world, including Asia, Europe, the Americas, and Africa.