Introduction for Corn grits making machine line

The corn can be cleaned up at one time (removing large, medium, small, powder impurities, moldy grains, stone removal, soil removal, iron removal) peeling, germ removal, root removal, black navel removal, crushing, grits making, extraction There are many functions such as flour, polishing, finished grits grading, etc. It can process more than 22 kinds of corn grits series products. The finished products are golden in color, uniform in grain, beautiful in appearance, positive in taste, no further processing, and can be directly entered into large supermarkets and grain and oil wholesale. market.

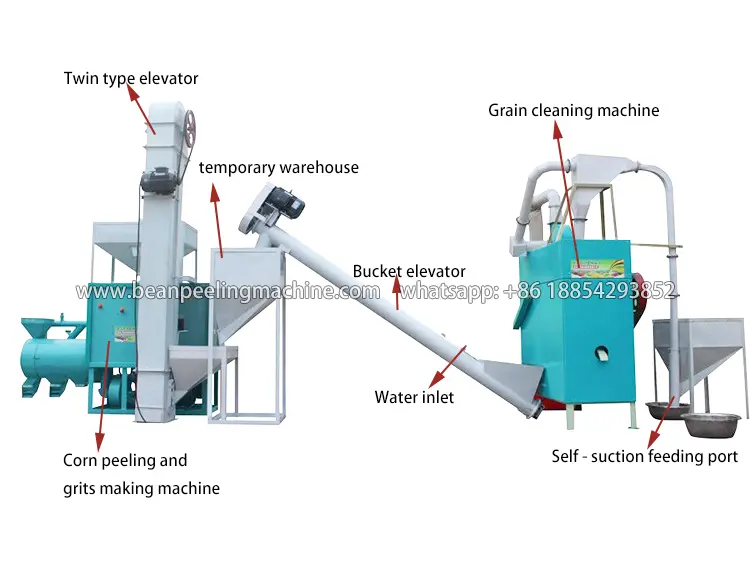

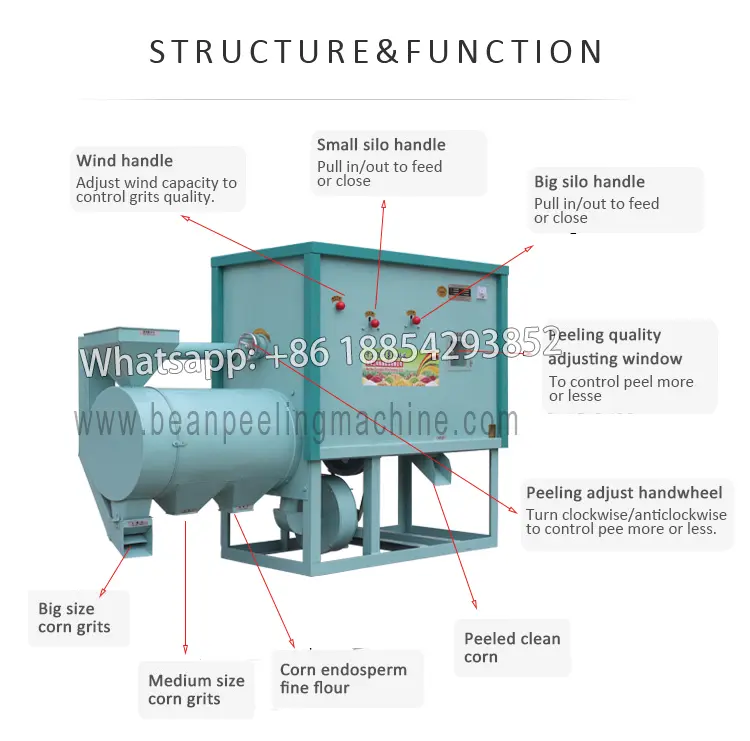

Structure for corn grits making machine

Cleaning:removing stone, iron, removing large, medium and small impurities

Peeling: :remove outer skin, take out root and black hilum, to get best nutrient part out of corn seed for further processing.

Grinding: grind peeled kernel into grits.

Grading: Grad grits into different mesh size.

Corn grits display

The finished corn grits are golden in color, uniform in size, and contain no bran or powder. They can be directly sold in supermarkets. The size of corn grits can be flexibly adjusted to meet the needs of different markets.

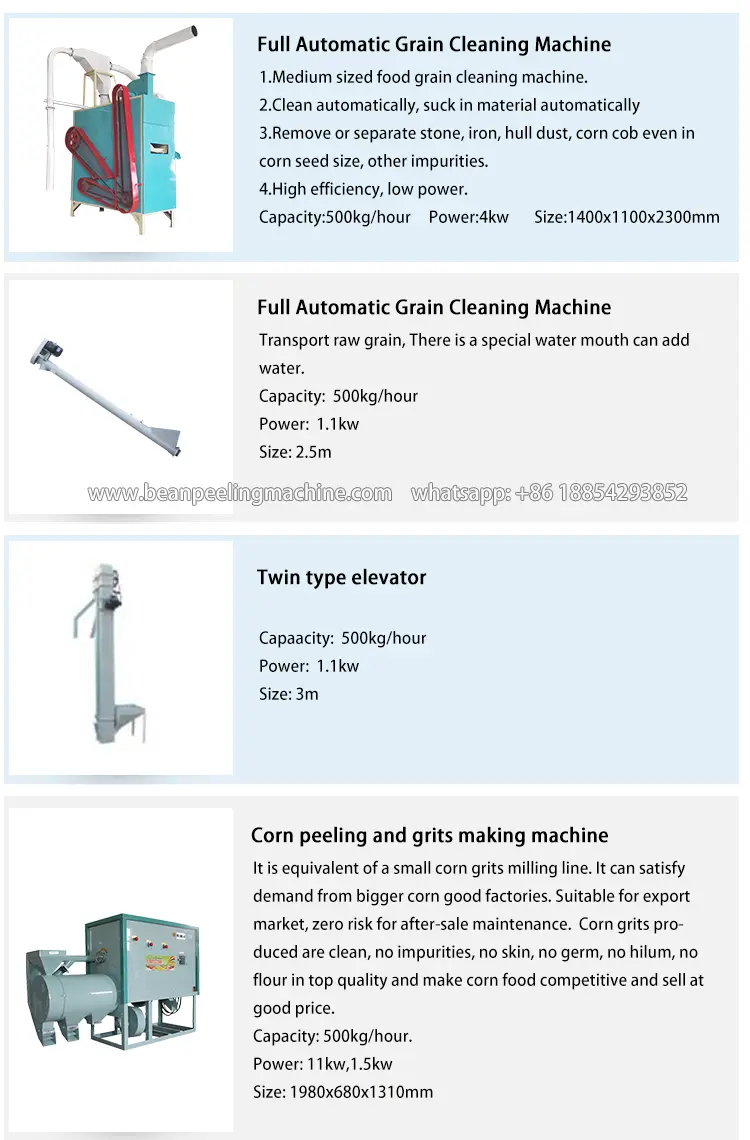

Related product for corn grits making machine

The production capacity of the product can be adjusted according to customer needs. The production capacity range is 200kg-4000kg/h.