1.Hot sale combined corn grits milling machine for Georgia introduce

A maize grits milling machine is a specialized piece of equipment used in the food processing industry to convert maize, also known as corn in some regions, into maize grits. Maize grits are coarsely ground maize kernels that can be used in various culinary applications, such as making porridge, breakfast cereals, and various corn-based dishes.

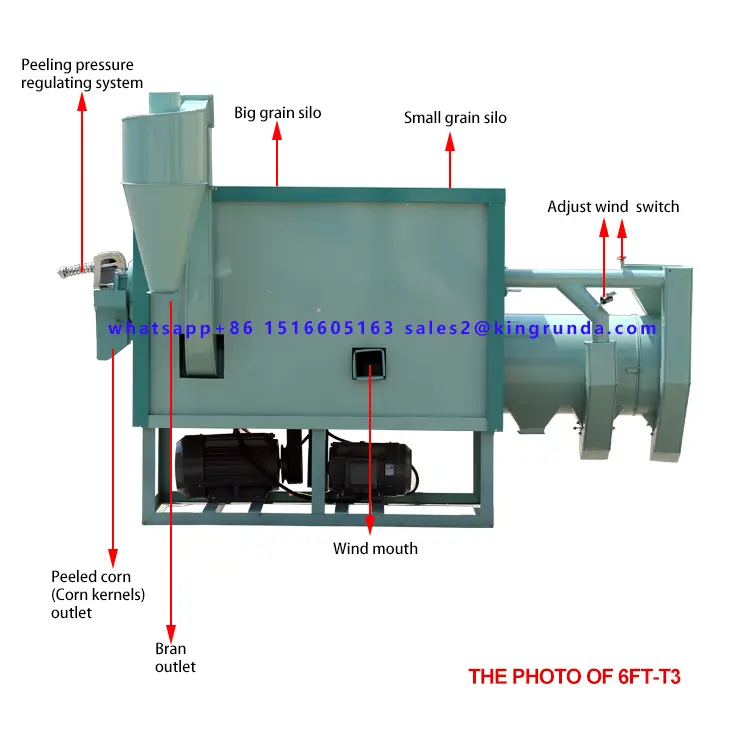

Main structure of maize grits milling machine

Hot sale combined corn grits milling machine for Georgia can work together with elevator to make the production fully automatically.

2.Hot sale combined corn grits milling machine for Georgia working effect

The equipment is easy to operate, beautiful in appearance, strong and durable, reliable performance, high output , Low power consumption, one-time cleaning, peeling, degerming, removing roots, taking black hilum, crushing, grits, grading, polishing, selection.

It can produce 22 kinds of finished grits, produced The corn grits are uniform, color and bright. The finished grits have a clean appearance, uniform particles, and bright color, and can be directly entered into large supermarkets and grain and oil wholesale markets.

Maize grits produced by our machines can be used as a primary ingredient in various food products or further processed into cornmeal, cornflour, or other maize-based products. They are a staple in many parts of the world and have a wide range of culinary and industrial applications.

3.Hot sale combined corn grits milling machine for Georgia advantages

1. Grinding Mechanism: The machine is equipped with a grinding or milling mechanism that effectively breaks down maize kernels into grits. This process typically involves crushing and grinding the maize to the desired coarseness.

2. Adjustable Settings: Many modern maize grits milling machines allow operators to adjust the coarseness or fineness of the resulting grits to meet specific product requirements.

3. Capacity: These machines come in various sizes and capacities to suit different production needs, from small-scale operations to large industrial facilities.

4. Efficiency: Maize grits milling machines are designed for efficiency, with features like high-speed milling to process a large quantity of maize in a relatively short time.

5. Separation of Endosperm and Bran: Some advanced machines have mechanisms to separate the endosperm (the starchy part) from the bran and germ, resulting in cleaner, grittier end products.

6. Easy Maintenance: To ensure smooth operation, these machines are typically designed for ease of maintenance, including cleaning and replacement of worn parts.

7. Safety Features: Safety measures are often incorporated to protect operators and prevent accidents during operation.

8. Automation: In industrial settings, automation features may be integrated to improve efficiency and reduce the need for constant manual supervision.