Introduction for Mung bean peeling mahcine

Mung bean peeling machine is a professional mung bean processing equipment for peeling mung beans. It can peel the mung bean bran as a single equipment, or process mung bean in the plant with high processing capacity and efficiency.

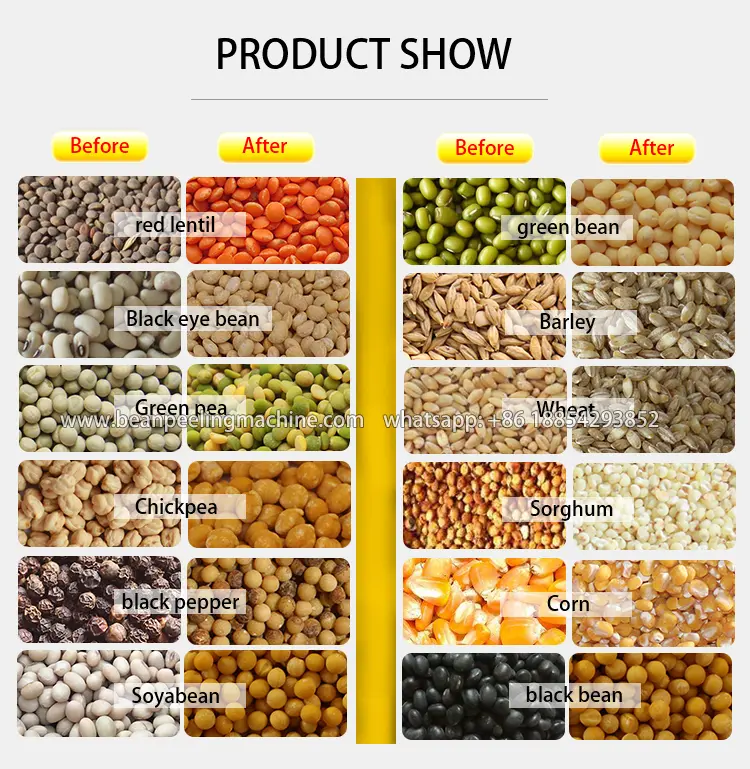

Machine Application:

Mung bean peeling machine can peel the following beans: soybean,broad bean,pea,mung bean,kidney bean,black soya bean,sword bean,pigeon pea,chickpea,lentil,cowpea,small red bean,butter bean,navy bean,phaseolus coccineus and so.

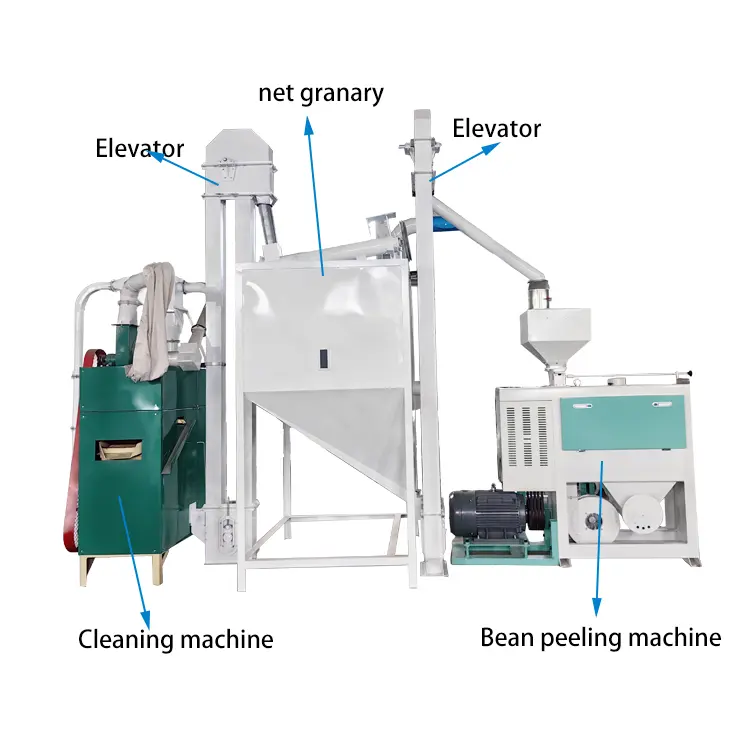

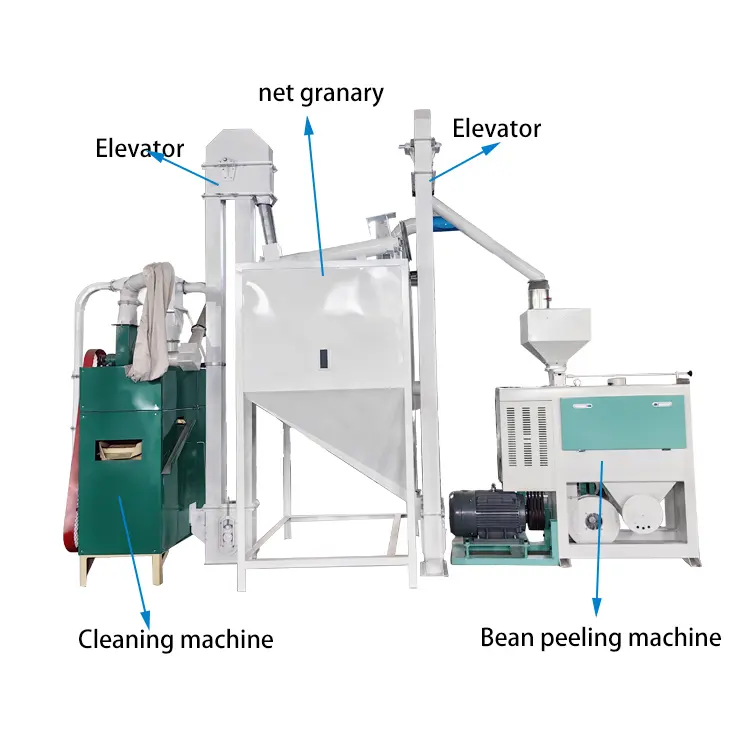

Mung bean peeling machine can also work in the bean processing plant:

This line incluede cleaning system and peeling system

Cleaning function

1. Medium sized food grain cleaning machine.

2. Clean automatically, suck in material automatically

3. Remove or separate stone, iron, hull dust, corn cob even in corn seed size, other impurities.

4. High efficiency, low power.

Peeling function

The machine uses emery blade in high rotary speed to continuously cut and rub the mung bean so as to damage bonding strength between germs and endosperms, and hull the skin of the mung bean to produce qualified mung bean kernels.

Mung bean peeling machine characteristics:

Peeling principle: The use of the latest manganese steel alloy diamond grinding roller, diamond grinding blade rotary cutting on both sides of the material in time to achieve the smallest crushing rate of peeling materials, the best peeling effect!

Equipment advantages:

1 Using pure dry peeling, peeling effect is good

2. The skin removal rate of the material can be adjusted according to the customer's requirements for the finished product

3. After peeling, the finished product has high grain size, less broken grain and high yield

4. High pressure skin suction air net, skin thoroughly separated, no kernel in the skin, kernel no skin, no powder in the bean skin

5. The whole machine has no wearing parts design, the core parts are peeled manganese steel alloy material, the main parts are quenched, anti-fatigue process treatment, sustainable continuous working time is long (can be continuously produced for one month)

6. All the air network pipes are thickened black iron material (3mm thick), after phosphating the surface, and then spray paint process, durable, never fade!

7. All the materials are cut by laser cutting machine, welding using the world's most advanced laser cold welding machine, strict guarantee of accuracy, strong and durable weld, there will be no air leakage phenomenon, to achieve dust-free production!

8. The main engine shell enamel thickened steel plate, valve design, clean and tidy, leaving no hidden dangers for future food safety inspection.