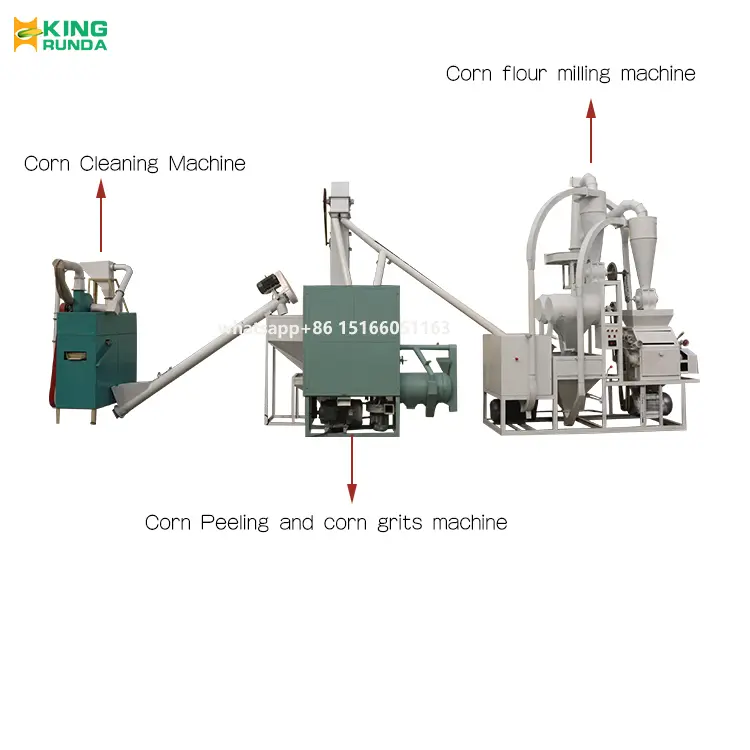

Automatic Maize grits and flour milling machine introduce

There are no special requirements for the production workshop, can be placed on the ground, a dragon straight line arrangement, but also according to the actual situation of the customer L-type arrangement, suitable for the place, flexible use, the entire production line from the original grain elevation, 1st cleaning, second peeling and grits milling, finally maize flour milling. black umbilical cord, de-embryonic, crushing and so on a number of processes at one time to complete the finished product corn kernel uniformity, colour and luster of the golden yellow, no micro-skin, no black spots, the use of dry peeling process.

2.Automatic Maize grits and flour milling machine details

3.Automatic Maize grits and flour milling machine line working process

4. Machine line advantage:

finished product corn kernel uniformity, colour and luster of the golden yellow, no micro-skin, no black spots, the use of dry peeling process. Unaffected by climate and weather changes, dry season, rainy season can be 24 hours continuous boot, installed capacity is small, low power consumption, occupies less workers (1 worker can be) on the workshop has no special requirements (ordinary houses can be installed) operation and maintenance is convenient (flat laying the height of the host computer 2 metres), the equipment is simple and easy to operate, an installation and commissioning is completed for a long time without the need to re-adjustment, all the host parts for the tempering (heat treatment), and the equipment is easy to operate, easy to use, and easy to use. All main machine parts are tempered (heat treatment), anti-fatigue, solid and durable.

5.Our showroom