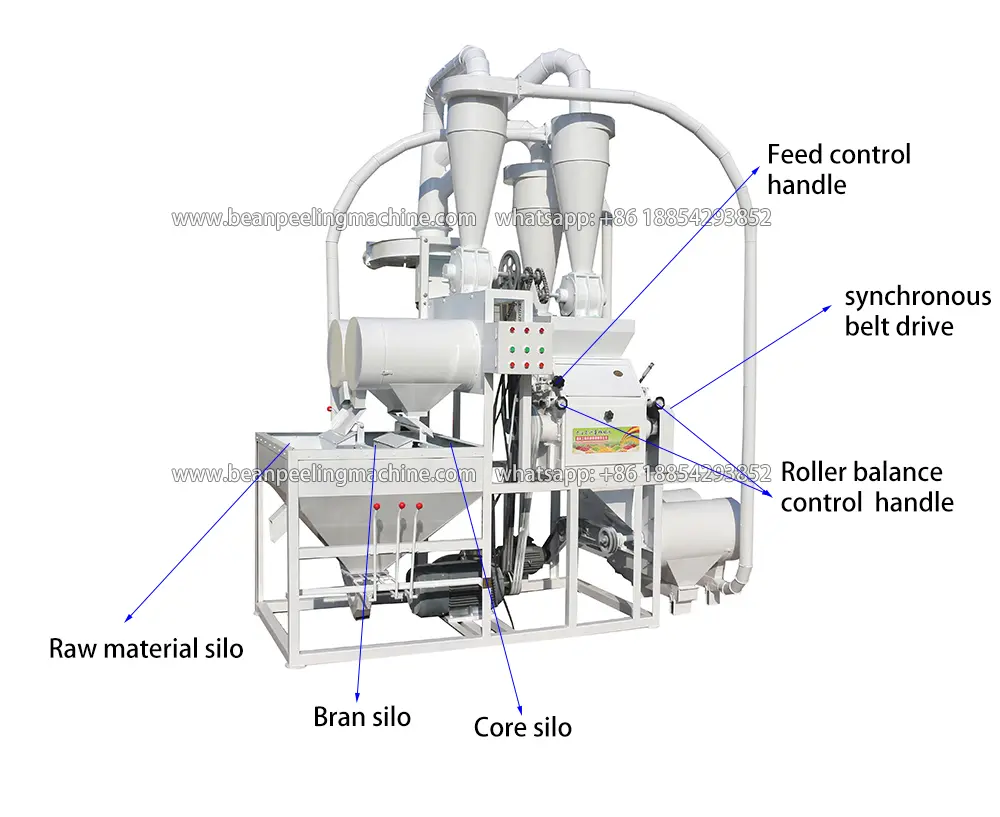

Introduction for Flour mill/semolina machine

It is our new high technology designed to produce high quality white wheat flour in different types. Structure is upgraded to have three silos and four round sifters. Two round sifters first extract wheat core to grind wheat core purely into wheat semolina (grits flour) and white wheat flour in highest quality. After extracting wheat core, wheat skin is separated and stored in middle silo for further grinding and flour extracted. Wheat core and wheat skin are milled separated. Skin/bran does not mix with wheat flour, that is why it produces high quality wheat flour.

in/bran does not mix with wheat flour, that is why it produces high quality wheat flour.

Whole procedure is automatic, wind transmit material. Feed grain into silo, automatically take grain to grind then auto sifting and receive output. Only needs one person to operate.

It is for high grade market. It places on ground, feed material from ground, no need elevator. Receive flour, bran from ground, easy to operate. It can produce wheat and cereal grain flour, wheat semolina flour, standard life. Flour fineness can be adjusted from 90 mesh to 120mesh.

Structure for Automatic semolina machine

Three silos designed to hold raw material, big bran, and wheat core separately.

Two round sifter first extracts wheat core.

Another two round sifter extracts wheat flour.

Wheat core and wheat bran are separated and get ground separately to have better quality.

Multi functionally produce different types flour and flexibly adjust types as per market.

How it works for Semlina machine

1st time extract wheat core

2nd time grind wheat core

3rd time grind wheat skin

Technical configuration & advantage

1. Machine body and pipes are powder coated for long time use, no color fading or scratches.

2. Metal parts are cut and produced by laser cutting machine and soldered by laser soldering machine for good precision to get good sealing.

3. Easy to adjust rollers as rollers have been done by dynamic balance test. Ex-work two rollers have been calibrated in parallel. Not like other suppliers, we only need to fix one roller with same space at two sides, adjust one handwheel to confirm rollers space.

4. Adopt most advanced synchronous belt drive system to reduce noise and good stability.

5. Four sifters can use four flour sieves in different mesh size according to market.

About our company

We are professional manufacturer for

Grain/Bean Dehuling & Peeling Machine for

lentil/pea/mung/faba bean/black eye bean/ chick pea

soyabean/tiger nut/oat/quinoa/millet/sorghum,etc

Maize Grits Milling Machine

Wheat Flour Milling Machine

851.webp)

337.webp)