886429.webp)

Inrodution for lentil peeling machine

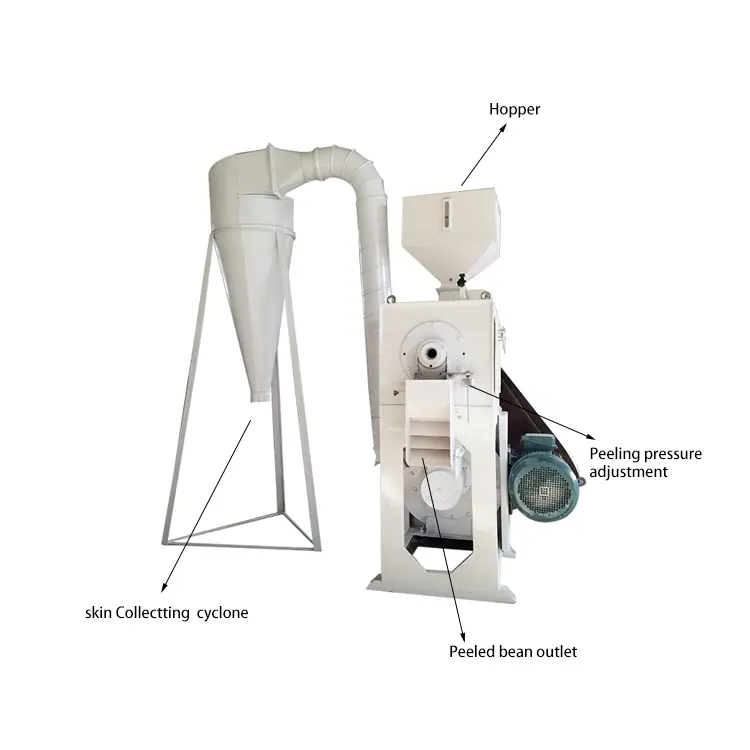

Lentil Peeling Machine connects with highly efficient air indraft system, which ensures reliability of bean bran discharging. It has strong cooling system so as to ensure high sanitation standard.

Lentil, also Massor Pulses, can be also called massor beans or lentil dal in Pakistan. Lentil Peeling Machine has the air draft dedusting system, which ensures the best sanitation condition.

Lentil Peeling Machine connects with highly efficient air indraft system, which ensures reliability of bean bran discharging. It has strong cooling system so as to ensure high sanitation standard.

r

Working principle for lentil peeling machine

The material is sent by the screw propeller to the center part of the lentil peeling machine- the peeling chamber. Then it utilizes emery roll that rotates with high speed to cut and rub the bean bran continuously and make bean bran separated. Then the material is conveyed to the discharging port and the peeling process is finished.

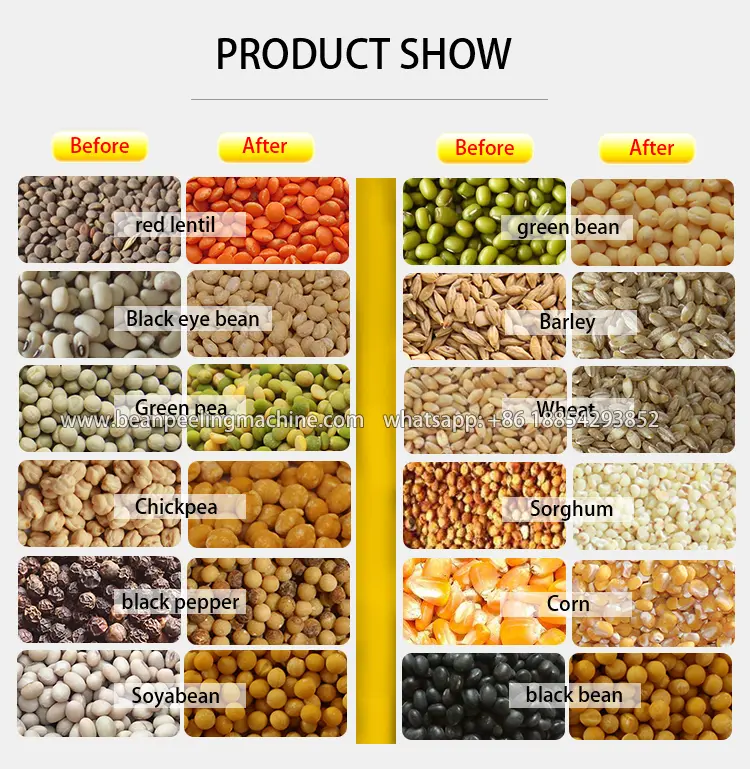

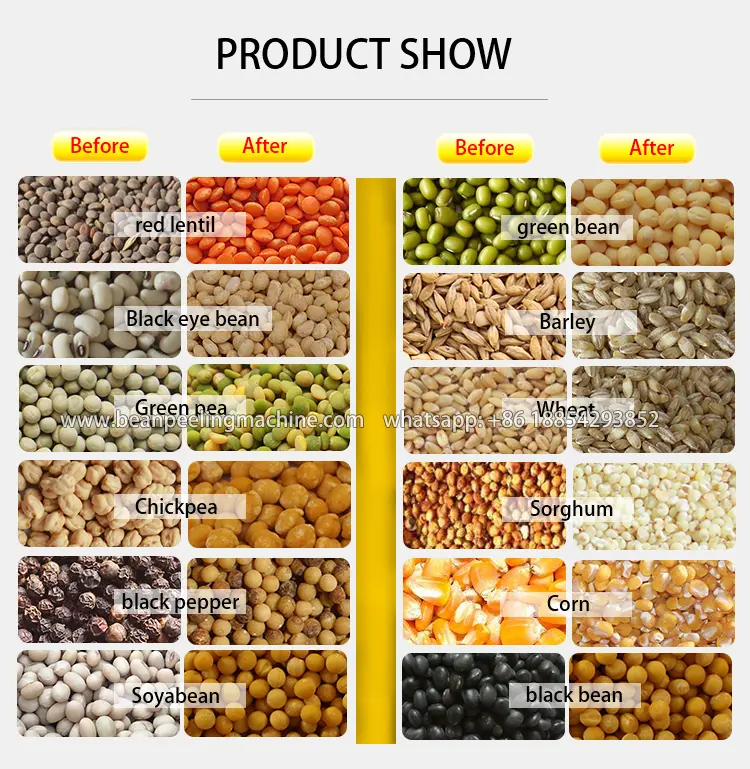

FInished product show for Lentil peeling machine

Usage:lentil, gram (moong / mung), soya bean, green peas, corn, wheat, barley, sorghum, black pepper, chickpeas, black eye bean. Please refer to follow photo.

Kingrunda Machinery is a manufacturer specializing in the manufacture of Lentil Peeling and Splitting Machine. The Lentil Peeling and Splitting Machine produced by our company are of stable quality, with few failures and simple operation. If you want to inquire about the price of Lentil Peeling and Splitting Machine, you are welcome to contact us.

Feature for lentil peeling machine

Easy operation and maintenance

Lentil Peeling and Splitting Machine is sieve plate and other accessories are quick-replaceable. It has durable emery roll and less wearing parts. This feature makes lentil peeling machine easily operated and maintained.

Reliable quality

Lentil Peeling Machine has uniform end products and reliable quality. There are different adjustment choices for you even in the peeling process.

High processing efficiency

Lentil Peeling Machine has moderate peeling process and high processing efficiency.

Air draft dedusting system

Lentil Peeling and Splitting Machine has the air draft dedusting system, which ensures the best sanitation condition.

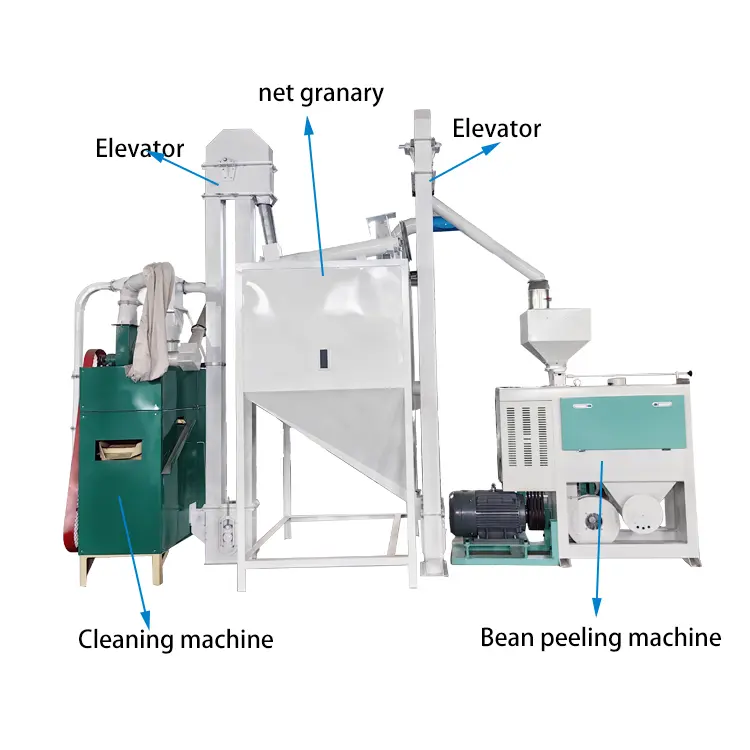

Lentil peeling machine can also work in the bean processing plant:

The plant can consist of cleaning, destoning, peeling, polishing, milling and other sections.

The machine uses emery blade in high rotary speed to continuously cut and rub the lentil so as to damage bonding strength between germs and endosperms, and hull the skin of the lentil to produce qualified lentil kernels.